In today's digital manufacturing and engineering landscape, reverse engineering is no longer a luxury—it's a necessity. Whether you're restoring legacy components, redesigning outdated parts, or replicating physical prototypes, reverse engineering allows you to convert real-world objects into precise digital 3D models. At Obsnap Instruments Penang, we specialize in providing 3D scanner solutions that make this transformation seamless, efficient, and accurate.

Our cutting-edge 3D scanner systems are designed to meet the demands of modern industries. With high-resolution capabilities, ease of use, and fast data capture, our 3D scanner are trusted by professionals in automotive, aerospace, manufacturing, and more. Backed by reliable software and technical support, Obsnap’s 3D scanner solutions are engineered to deliver precision and performance in every scan.

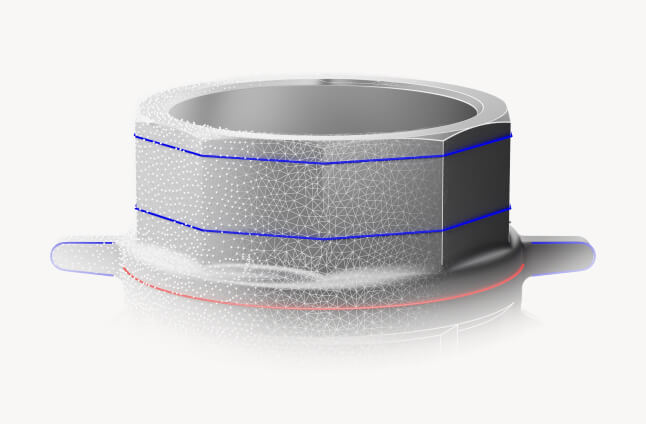

Reverse engineering is the process of analyzing and digitizing an existing object to reconstruct its design as a 3D CAD model. This method is especially useful when CAD files are lost, outdated, or never existed. With a 3D scanner, users can capture the geometry of an object and convert it into editable mesh or CAD-ready data.

Reverse engineering powered by a 3D scanner is used to:

Reproduce damaged or discontinued parts

Modify or enhance existing designs

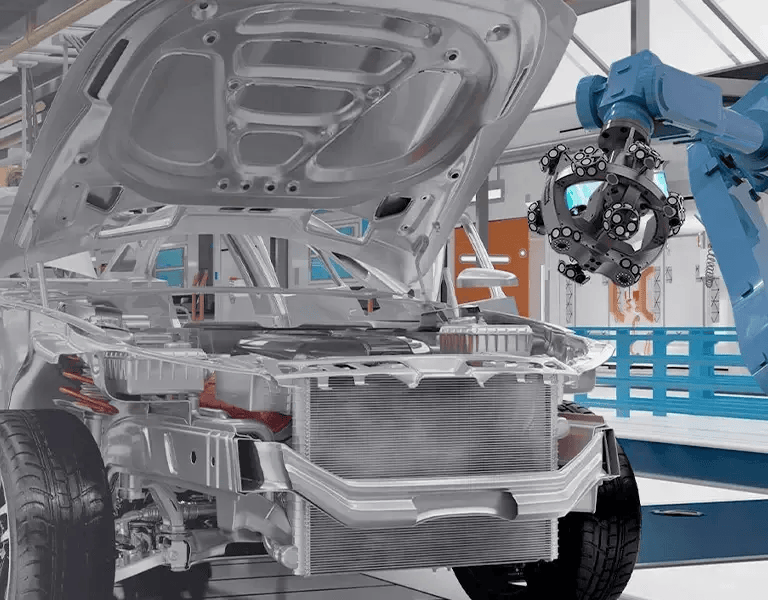

Fit new parts into existing assemblies

Improve manufacturing processes

Benchmark competitor products

Create digital archives of physical objects

By utilizing a 3D scanner, you can significantly reduce development cycles while increasing design accuracy and product quality.

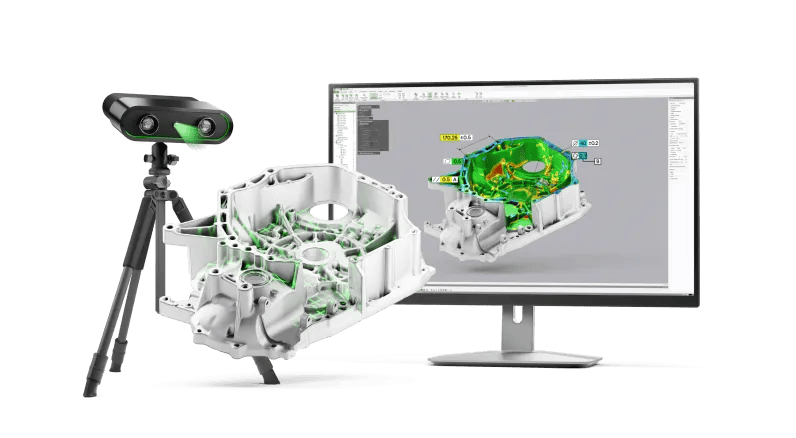

At Obsnap Instruments Penang, we provide a full range of handheld and optical 3D scanners that simplify reverse engineering for every industry. Our systems are built with advanced laser or structured-light technology to ensure accurate surface capture — from small precision components to large industrial assemblies.

Our 3D scanner offerings are paired with intuitive software that enables you to clean, align, optimize, and export your scan data for CAD use. Whether you're scanning metals, plastics, composites, or complex textures, our 3D scanners are designed to handle diverse materials and finishes with ease.

Obsnap’s 3D scanner lineup ensures you get the most from your reverse engineering workflow — from scanning to design and production.

.jpg)

.jpg)

Key Benefits of Using a 3D Scanner for Reverse Engineering

Our 3D scanners deliver exceptional resolution for capturing intricate features, edges, and curves — making them ideal for reverse engineering parts with freeform or organic shapes.

Compared to manual methods, a 3D scanner significantly reduces scanning time. The generated mesh is processed and ready for CAD integration almost instantly, streamlining your workflow.

Every 3D scanner we offer meets metrology-grade standards, providing high-accuracy data essential for inspection, quality control, and manufacturing.

Our 3D scanners work across various industries and applications, offering flexibility whether you’re in automotive design, aerospace engineering, consumer products, or academic research.

Obsnap’s 3D scanners feature intuitive interfaces and plug-and-play functionality, making it easy for professionals at any skill level to operate them effectively.

Legacy Part Replication – Use a 3D scanner to recreate old or worn-out parts when original documentation is missing.

Product Redesign & Optimization – Modify and enhance existing components with accurate scan data.

Tooling & Mold Inspection – Verify tooling precision with a 3D scanner before production.

Cultural & Heritage Preservation – Digitize artifacts and sculptures without contact or risk of damage.

Competitor Product Benchmarking – Analyze product features using a 3D scanner for competitive analysis.

Assembly Fit Verification – Scan and verify alignment between parts to prevent assembly issues.

Quality Control & Dimensional Inspection – Validate manufacturing tolerances with high-accuracy 3D scannermeasurements.

With more than 20 years of experience serving Malaysian industries, Obsnap Instruments Penang is a trusted provider of metrology and measurement technologies. Our commitment to innovation, service, and customer success makes us a top choice for businesses seeking reliable 3D scanner solutions for reverse engineering.

We don’t just sell 3D scanners—we provide a complete solution, including:

Technical consultation

On-site product demonstrations

Professional training

After-sales support and maintenance

Whether you're a design engineer, manufacturing specialist, or quality control manager, our goal is to equip you with a 3D scanner solution that fits your workflow and boosts your productivity.

Ready to take your reverse engineering capabilities to the next level? Contact Obsnap Instruments Penang to learn more about our 3D scanner systems, request a demo, or schedule a consultation. Our team is here to help you transform your physical parts into digital perfection — with speed, accuracy, and confidence.

📞 Call Us Now | ✉️ Email Our Experts | 📅 Request a Demo

(+60124010590) | [email protected] |

Singapore

Singapore