Pulley systems are critical components in mechanical power transmission applications including motors, pumps, conveyors, and process machinery. This document provides professional-level procedural guidance for the installation and removal of QD (Quick Detachable) and Taper Lock pulley systems.

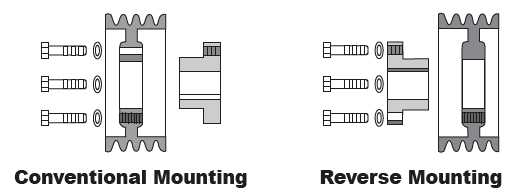

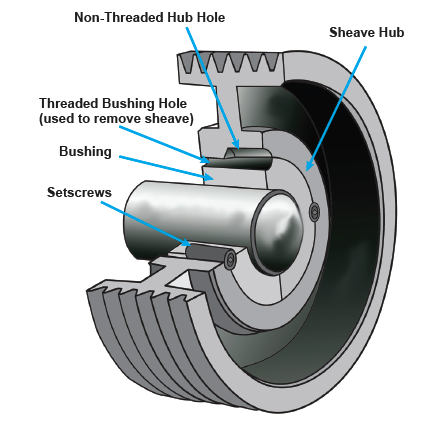

QD pulleys utilize a flanged, split-tapered bushing to secure the pulley to the shaft. This design promotes reliable clamping force, accurate positioning, and simplified removal.

| Configuration Element | Description |

|---|---|

| Flange Position | Outward facing (visible and accessible) |

| Application | General machinery and standard maintenance environments |

| Serviceability | High – field access is simplified |

| Configuration Element | Description |

|---|---|

| Flange Position | Inward, between pulley hub and equipment housing |

| Application | Compact machine layouts or restricted access conditions |

| Serviceability | Moderate – service may require extended tools or repositioning |

Required Tools: Torque wrench, hex keys, anti-seize compound (threads only), emery cloth, PPE.

Taper Lock systems are engineered for precise concentricity at medium-to-high rotational speed applications. The bushing clamps concentrically around the shaft when mounting screws are torqued, providing high security and alignment accuracy.

| Requirement | Reason |

|---|---|

| Do not lubricate taper contact surfaces | Prevents slippage and torque failure |

| Mandatory torque wrench usage | Ensures proper clamping force |

| No direct hammer impact | Protects structural integrity of pulleys and bushings |

| Lockout/Tagout compliance | Ensures technician safety |

| Recheck torque after initial run | Compensates for thermal settling |

Correct installation and removal of QD and Taper Lock pulley systems ensures mechanical performance, alignment stability, and extended service life. By adhering to professional procedures, torque specifications, and engineering safety practices, downtime is reduced and asset reliability is improved. This guide establishes a professional standard for industrial maintenance and equipment servicing.

Singapore

Singapore