Behind every high-performing product lies a relentless journey of research, testing, and refinement. At Space Products, our aluminium performance louvers are the result of years of dedicated R&D—driven by one goal: to engineer a solution that balances airflow efficiency with superior rain defence.

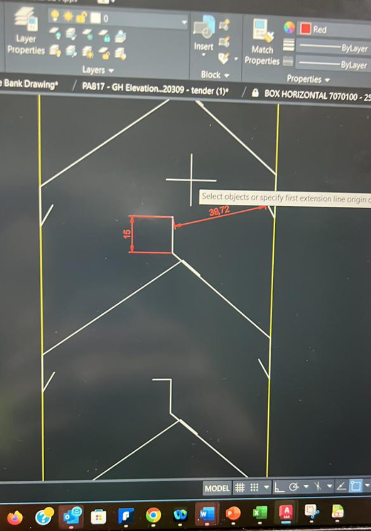

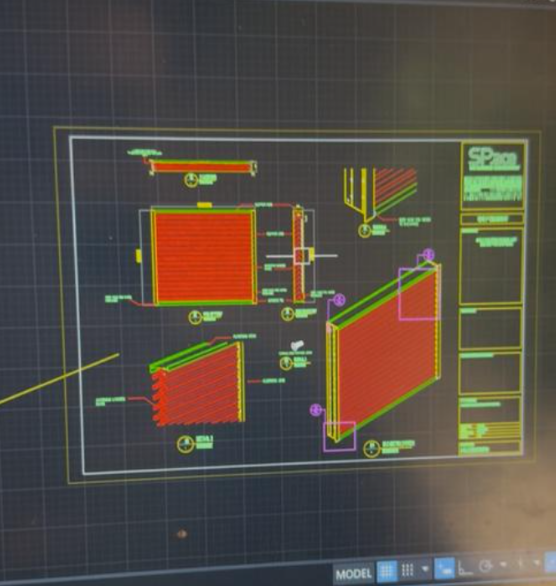

From the earliest design stage, our team conducted in-depth research, gathering technical intelligence from global references and industry benchmarks. These insights were translated into physical prototypes, which were carefully modelled and fabricated in our factory to simulate real-world conditions.

What follows is a visual walkthrough of our comprehensive R&D journey—each stage reflecting our commitment to performance, reliability, and continuous improvement.

As architectural façades become more expressive and buildings increasingly rely on natural and mechanical ventilation, the role of louvers has evolved beyond aesthetics alone. While single-bank aluminium louvers with tighter blade spacing are often perceived as sufficient for rain protection, real-world conditions tell a more complex story.

Rain does not always fall vertically. In high-rise buildings, open terrains, coastal environments, and mechanically ventilated spaces, rain is frequently wind-driven and pressure-assisted. Under these conditions, water behaves differently—travelling as fine droplets and surface films that can be carried through openings when airflow is present.

This is where the distinction between architectural rain screens and performance louvers becomes critical.

Single-bank louvers, such as close-spaced Z-blade systems, are highly effective as architectural rain screens. In sheltered locations or non-critical areas, they can successfully deflect rain and meet both visual and functional requirements. For many façade applications, this solution is appropriate and cost-efficient.

However, when louvers are required to perform under:

wind-driven rain,

active air intake or exhaust,

pressure differentials across the building envelope,

or exposure at high elevations,

a different level of engineering is required.

Double and triple bank performance louvers are not designed to “block” rain by geometry alone. Instead, they are engineered to manage rain while air is moving through the opening.

By introducing multiple stages within the louver system, performance louvers:

interrupt rain momentum,

promote droplet separation from airflow,

allow water to drain safely before it reaches the interior,

and maintain controlled airflow performance.

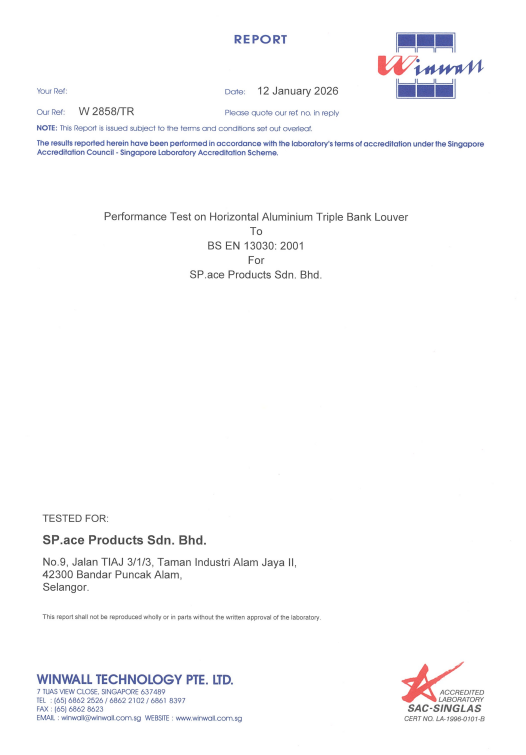

This multi-stage approach is precisely why performance louvers are tested under wind-driven rain and airflow conditions, rather than judged solely by blade spacing or visual density.

A frequent concern raised is whether additional louver banks may create mist or water droplets near the façade. In practice, such issues are rarely caused by the presence of a second or third bank alone.

Water carry-over is typically a result of:

excessive face velocity,

insufficient louver area,

or improper detailing near pedestrian zones.

When performance louvers are correctly sized and designed to operate within recommended airflow velocities, droplet carry-over is minimised. Where louvers are installed near walkways or building edges, thoughtful detailing—such as setbacks, drip edges, or drainage provisions—ensures pedestrian comfort without compromising performance.

It is true that double and triple bank performance louvers carry a higher initial cost compared to single-bank systems. This cost reflects:

increased material and fabrication complexity,

extensive R&D and prototyping,

and independent laboratory testing under severe conditions.

However, the decision to specify performance louvers is less about cost comparison and more about risk management. In critical areas such as data centres, plant rooms, generator rooms, electrical substations, and high-exposure façades, the cost of water ingress, equipment damage, corrosion, and future rectification far outweighs the initial premium of a performance-engineered solution.

At Space Products, we do not believe in a one-size-fits-all approach. Single-bank louvers remain an excellent solution for appropriate locations. Double and triple bank performance louvers are specified when the environment, exposure, and function demand a higher level of protection.

By aligning louver selection with real operating conditions—rather than appearance alone—architects and engineers can achieve façades that are not only visually compelling, but also resilient, reliable, and future-ready.

This journey represents more than just product development—it reflects our belief that performance must be proven, not assumed. Through rigorous testing and continuous refinement, our aluminium performance louvers are engineered to meet demanding environmental conditions while supporting safe, efficient building ventilation. For more information regarding our aluminium performance louvers, please Whatsapp or give us a call now.

Philippines

Philippines