3D Scanning: Advancing the Future of Automotive Part Manufacturing and Repair

by OBSNAP PENANG

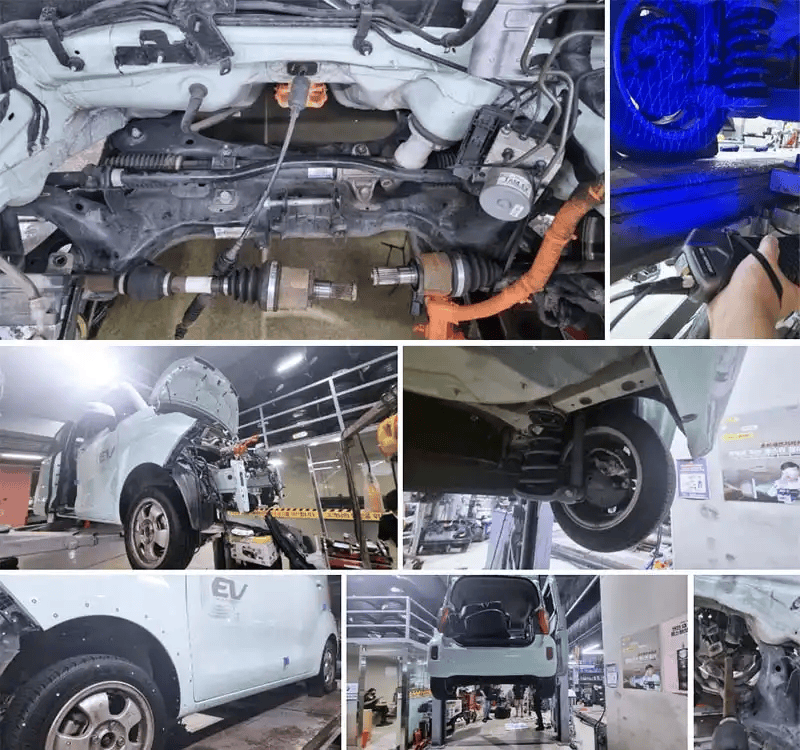

The automotive industry is undergoing a significant transformation, driven by technological advancements and increasing consumer demands for precision and efficiency. As vehicles become more complex, the need for accurate and detailed measurements of automotive parts has intensified. 3D scanning technology has emerged as a crucial tool, offering precise and comprehensive data that supports the production and maintenance of automotive parts.

Addressing Measurement Challenges in Automotive Parts

Automotive parts, ranging from exterior body panels to intricate interior components, often present measurement challenges due to their complex geometries, reflective surfaces, and limited access to tight spaces. Traditional measurement methods, such as calipers and coordinate measuring machines (CMM), can be time-consuming and may not capture the full 3D data of intricate parts. These limitations necessitate the adoption of advanced 3D scanning technologies that can overcome these challenges and deliver superior results.

Scantech’s SIMSCAN: A Game-Changer in 3D Scanning

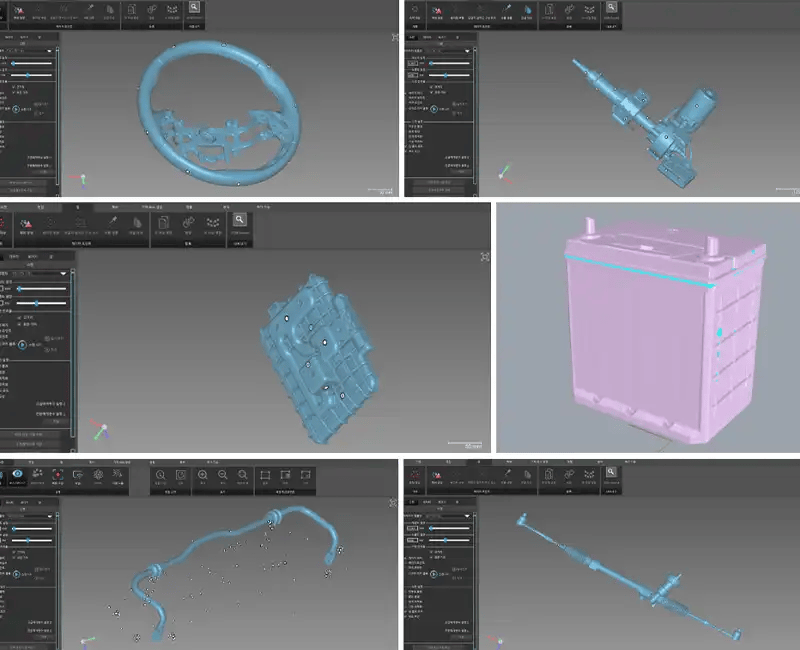

Scantech’s SIMSCAN 3D (https://shorturl.at/pitMU) scanning solution addresses these issues with high-precision scanning, versatility on various surfaces, a compact design for confined spaces, and fast scanning speeds. Its non-contact measurement ensures delicate parts remain undamaged, and advanced software aids in precise alignment, overcoming environmental variables and enhancing manufacturing and repair processes.

Key Features of SIMSCAN:

-

High-Speed Scanning: The SIMSCAN can capture high-precision data at an impressive speed of 2.8 million measurements per second, allowing for efficient scanning of multiple parts within tight timeframes.

-

High Accuracy: With an accuracy of up to 0.020 mm, SIMSCAN ensures precise alignment and comprehensive data capture, enhancing the overall accuracy of the inspection process.

-

Detailed Interior Scanning: Its compact design and high precision enable effective scanning of interior components, capturing every detail with high accuracy.

-

Adaptability to Various Surfaces: SIMSCAN excels in scanning dark and reflective surfaces, which are common in automotive parts, saving significant time and effort and streamlining the entire inspection process.

Benefits of 3D Scanning in Automotive Parts Manufacturing and Repair

The adoption of 3D scanning technology offers several benefits to automotive manufacturers and repair shops:

-

Ensuring Fit: SIMSCAN ensures that new or replacement parts will fit correctly with existing components, thanks to its accurate scanning capabilities.

-

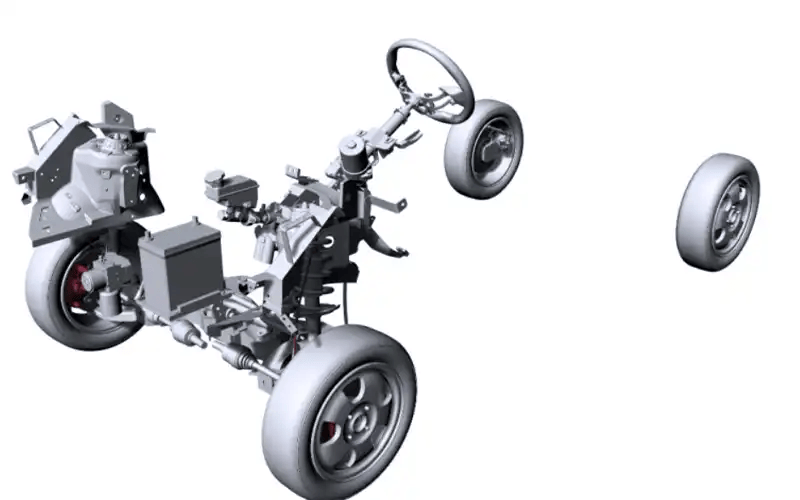

Reproducing Parts: The high-resolution scanning capabilities enable capturing intricate details of existing parts, facilitating the creation of precise digital models for reproducing parts that need to be replaced.

-

Maintenance Records: Maintaining accurate records of parts and their conditions over time is simplified, aiding in effective maintenance and repair operations.

-

Custom Modifications: The portable SIMSCAN allows for quick and precise scanning of existing parts, enabling the design of custom or modified parts that fit seamlessly.

Conclusion

Scantech’s SIMSCAN 3D scanning solution has proven to be a game-changer in the automotive industry, addressing significant challenges associated with scanning automotive spare parts. Its high-speed and precise 3D scanning capabilities, along with the ability to handle difficult surfaces and confined spaces, result in a highly efficient and effective scanning process. The detailed and accurate 3D data obtained from the scans enable manufacturers and repair shops to perform precise 3D modeling, ultimately contributing to the advancement of their services in the automotive industry.

Get Started with 3D Scanning Today

Ready to take your reverse engineering capabilities to the next level? Contact Obsnap Instruments Penang to learn more about our 3D scanner systems, request a demo, or schedule a consultation. Our team is here to help you transform your physical parts into digital perfection — with speed, accuracy, and confidence.

(https://shorturl.at/pitMU)

Visit our page : www.obsnappg.com

Philippines

Philippines