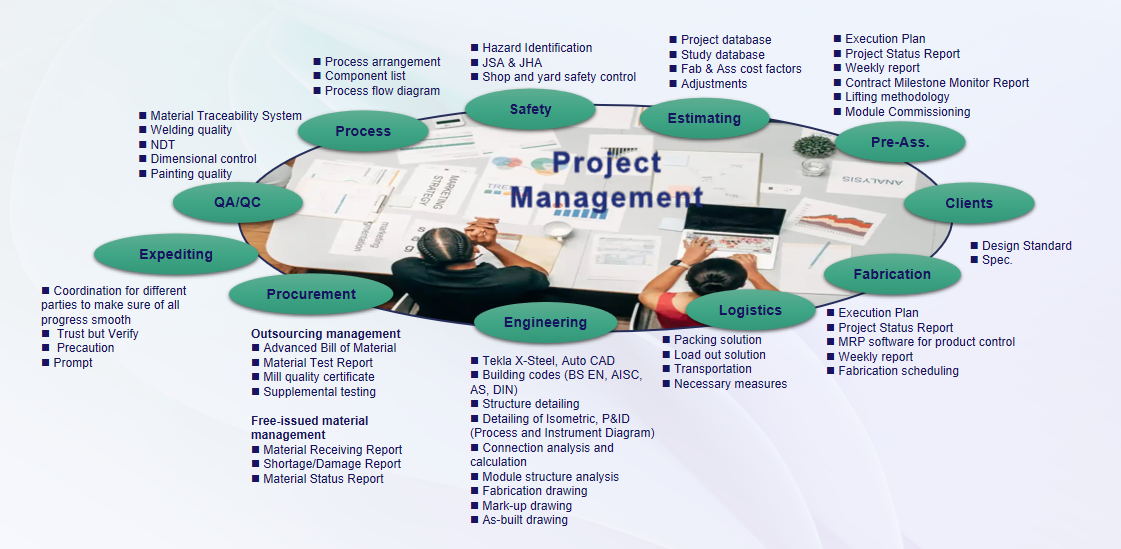

With 20 years of experience in the international steel structure industry, ForMc is capable of providing professional one-stop services: engineering, procurement, expediting, supply survey, third-party inspection and project management. We are committed to delivering on team, on time and on site for clients worldwide.

Strict quality compliance: Certified inspectors adhere to AISC, EN, BS, CSA, and CWB standards, conducting full-process inspections to ensure product safety and quality.

Efficient risk control: Scientific expediting plans and contingency solutions address potential delays, risk warnings, and transportation challenges.

Industrial plants, buildings, bridges, infrastructure, petrochemical facilities, environmental protection and new energy projects and data processing centers, etc.

Our inspection team possesses extensive experience across diverse industries and has an in-depth understanding of international standards and requirements. We manage every project with a dedicated Project Manager supported by a team of senior inspectors.

Safety First: Every inspector undergoes comprehensive Safety, Health, and Environment (HSE) training specific to the site prior to deployment. To ensure ongoing safety, our dedicated safety officers conduct unannounced site inspections, guaranteeing a secure working environment at all times.

Technical Proficiency: Inspectors also receive specialized training on the specific national standards, project specifications and procedural requirements. This ensures every team member fully understands the project scope, thereby meeting our clients' exact quality expectations.

We hold regular coordination meetings with both clients and manufacturers. This collaborative approach allows us to promptly identify and correct issues, issue early warnings for potential risks and analyze reasons to implement effective solutions. Our goal is to ensure projects meet stringent quality standard and are delivered on schedule.

We are fully capable of providing inspection services compliant with the following standards:

All our inspectors are certified professionals who strictly adhere to client requirements. In the rare event of a client complaint regarding personnel performance, we guarantee a swift replacement to maintain service quality.

Furthermore, we are capable of providing professional Supply Survey services for your steel structure-related products. Our goal is to help you minimize end-user complaints and prevent costly claims arising from quality concerns.

Malaysia

Malaysia