High-Capacity Centrifugal Fan Acoustic Enclosure at ALCOM

System: Industrial Centrifugal Fan – Process Ventilation / Exhaust

Scope: Design, Fabrication & Installation, and integration with existing ducting

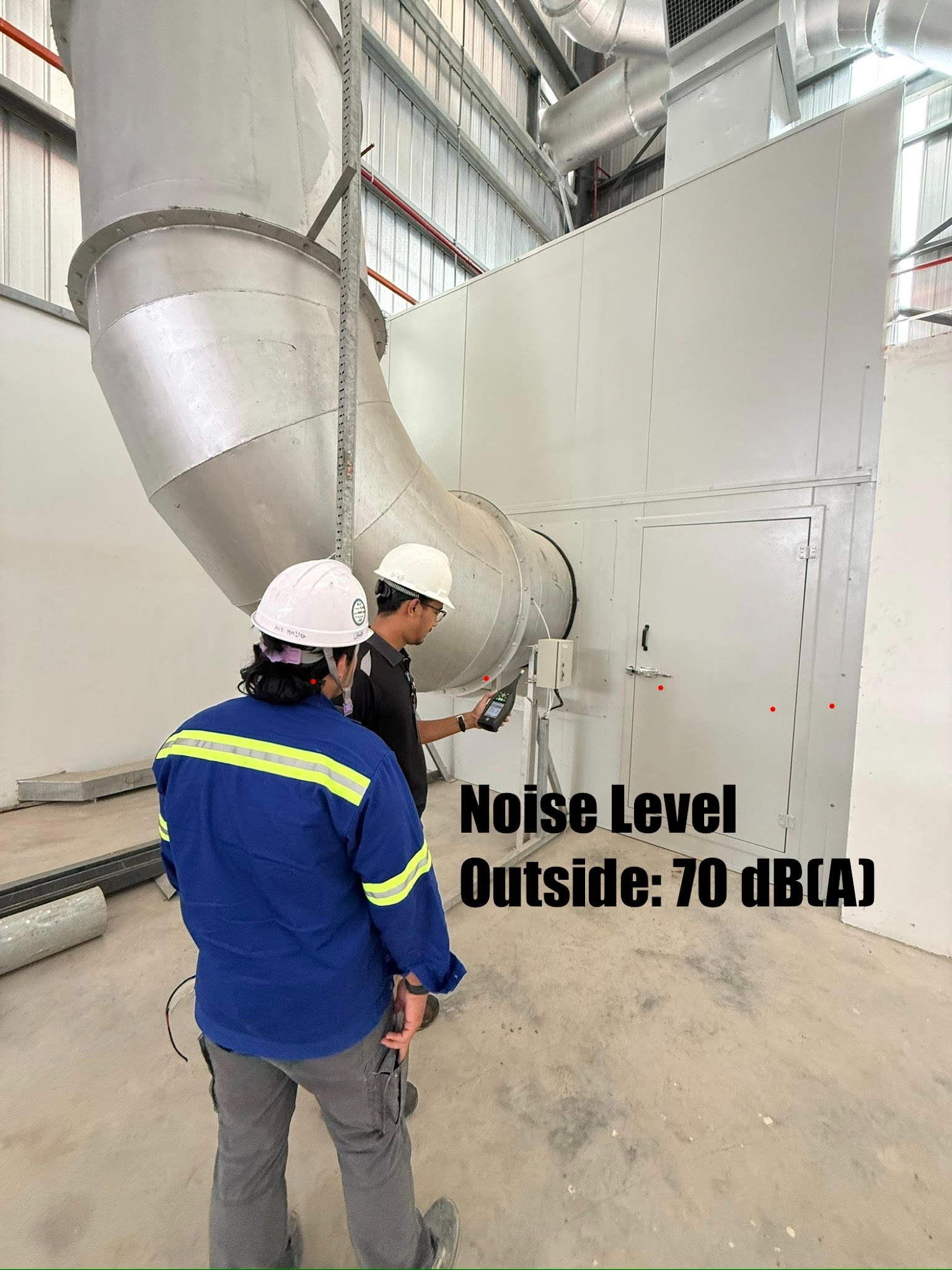

Result: Noise reduction from 95 dBA to 70 dBA

OVERVIEW

At ALCOM’s aluminum processing facility, a high-capacity centrifugal fan plays a critical role in driving the plant’s ventilation and exhaust system. Like many heavy-duty centrifugal fans used in aluminum plants, the unit operates continuously at high airflow and pressure, handling hot process air and fumes essential for stable production. While the fan performed exactly as designed, it also produced a familiar industrial challenge—high noise. Initial measurements recorded sound levels of approximately 95 dBA in the surrounding work area.

Installation was carried out under strict safety controls. Much of the work was performed at height and within confined structural zones above the fan. Full harness systems, controlled access platforms, and complete PPE enforcement were applied throughout the project. The lifting, positioning, and alignment of large acoustic panels required close coordination between team members to ensure both accuracy and safety. The work progressed smoothly without any safety incidents.

Upon completion, post-installation measurements confirmed a noise reduction from 95 dBA to approximately 70 dBA, representing a significant drop in acoustic energy and a major improvement in the working environment. Most importantly, the centrifugal fan continues to operate at its original duty point, with airflow capacity, pressure performance, and process stability fully preserved.

For ALCOM, the outcome delivered precisely what was required—a quieter, safer workplace without sacrificing production reliability. For ISTIQ, it stands as a firm reference for the effective acoustic treatment of large centrifugal fan systems through engineered containment rather than equipment replacement.

Malaysia

Malaysia