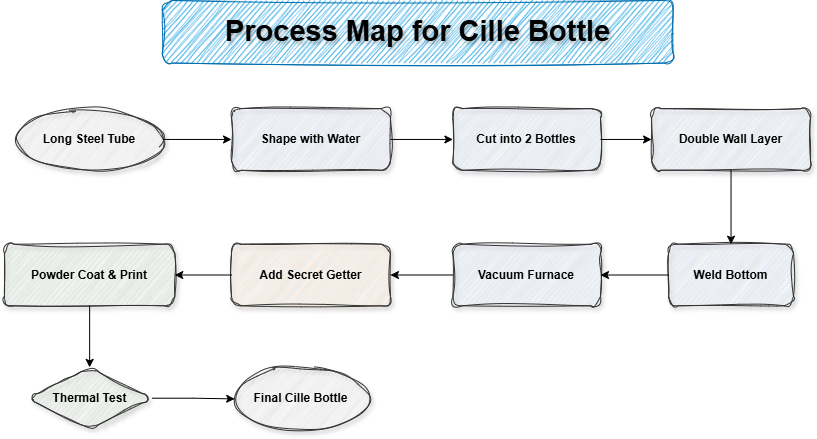

A premium stainless steel bottle is more than just a container; it is a high-tech thermal insulator. From water-pressure shaping to the use of medical-grade materials, here is the sophisticated process behind every Cille bottle.

Quality starts with the raw metal. At Cille, we utilize 304 food-grade and 316 medical-grade stainless steel. While 304 is the industry standard for durability, our 316 steel contains molybdenum, providing superior resistance to corrosion from acidic drinks like coffee or fruit juices.

Using hydroforming, high-pressure water is pumped into the steel tube while it is locked inside a mold. This forces the steel to expand into the bottle’s silhouette, maintaining a consistent wall thickness and superior structural strength.

Efficiency is key. The hydroformed tube is designed to form two bottle bodies joined at the neck. Once shaped, the tube is cut precisely in the middle, creating two separate shells ready for assembly.

To achieve insulation, an inner shell (often 316 steel for better drink purity) is "nested" inside an outer 304 shell. This creates a "jacket" or gap between the two layers which will become the vacuum barrier.

Before sealing, we add a "Getter"—a specialized chemical material—inside the gap. This acts as a microscopic sponge, absorbing stray gas molecules that emerge from the metal over time. This ensures the vacuum stays "hard" and effective for years, not just months.

.png)

The bottle enters a vacuum furnace where air is evacuated. Every bottle then undergoes a Heat Insulation Test using infrared cameras. If the outer shell stays cold while the inside is hot, the vacuum is perfect. If "hot spots" appear, the bottle is rejected.

Passed bottles move to surface treatment: polishing, durable powder coating, and finally, precision laser engraving or UV printing of the Cille logo.

Experience the difference between 304 and 316 steel in person. Our Puchong showroom features our full range and professional team ready to assist with retail or corporate gifting.

Operating Hours: 9:00AM- 6:00PM

What’s Inside: Full product display, color samples, and corporate gifting consultations.

Vietnam

Vietnam