Model :

| Use machinery | Basic dynamic load rating | lower limit of fs |

| General industrial machinery | When there is no vibration or shock | 1~1.3 |

| When there is vibration or impact | 2~3 |

.png)

| Main dimensions | Work surface size | |||||||||||||||

| Nominal model |

Maximum stroke |

Width W -0.2 -0.4 |

Height M ±0.1 |

Length (L) |

Mass (kg) |

Workbench mounting thread Hole position |

Side assembly threaded hole locations | |||||||||

| B | nxF | G | S | B1 | G1 | G2 | b1 | t1 | S1xl | T | ||||||

| VRU-1025 | 12 | 30 | 17 | 25 | 0.08 (0.04) | 10 | 12.5 | M2 | 18.4 | 7.5 | 2.5 | 12 | 2.5 | M2x4 | 11 | |

| VRU-1035 | 18 | 35 | 0.11 (0.05) | 1x10 | 4.5 | |||||||||||

| VRU-1045 | 25 | 45 | 0.15 (0.07) | 2x10 | 6 | |||||||||||

| VRU-1055 | 32 | 55 | 0.18 (0.09) | 3x10 | 7.5 | |||||||||||

| VRU-1065 | 40 | 65 | 0.21 (0.1) | 4x10 | 8.5 | |||||||||||

| VRU-1075 | 45 | 75 | 0.24 (0.12) | 5x10 | 11 | |||||||||||

| VRU-1085 | 50 | 85 | 0.27 (0.13) | 6x10 | 13.5 | |||||||||||

| VRU-2035 | 18 | 40 | 21 | 35 | 0.2 (0.09) | 15 | - | 17.5 | M3 | 25 | 10 | 3 | 16 | 3.4 | 14 | |

| VRU-2050 | 30 | 50 | 0.26 (0.13) | 1x15 | 4.5 | |||||||||||

| VRU-2065 | 40 | 65 | 0.34 (0.17) | 2x15 | 7 | |||||||||||

| VRU-2080 | 50 | 80 | 0.42 (0.21) | 3x15 | 9.5 | |||||||||||

| VRU-2095 | 60 | 95 | 0.5 (0.25) | 4x15 | 12 | |||||||||||

| VRU-2110 | 70 | 110 | 0.58 (0.29) | 5x15 | 14.5 | |||||||||||

| VRU-2125 | 80 | 125 | 0.66 (0.33) | 6x15 | 17 | |||||||||||

| Base surface size Mounting hole location |

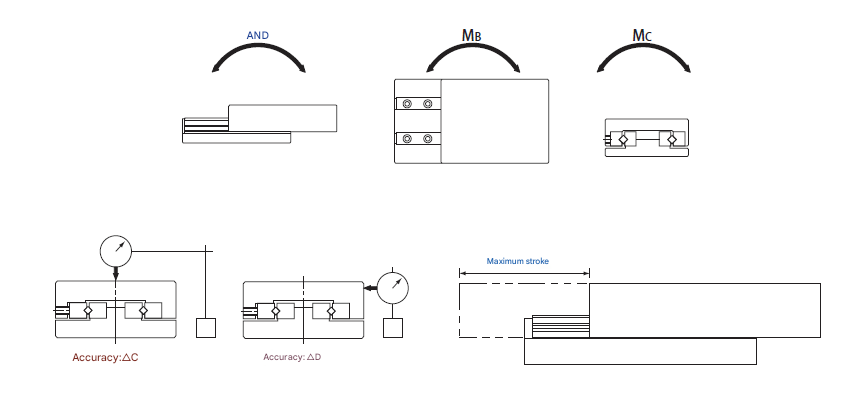

Basic load rating | Static allowable moment | Accuracy μm | |||||||||||||||

| H | K | dxDxh | D1 | m1 | A | m2 | B2 | f1 | f2 | g | Roller Quantity Z |

C KN | CO KN | MA N.m | MB N.m | MC N.m | ΔC | ΔD |

| 5.5 | 6.5 | 2.55x4.1x2.5 | 4.1 | M2 | 9 | M2 | 22 | 18 | - | 3.5 | 5 | 0.46 | 0.61 | 1.52 | 1.25 | 4.12 | 2 | 4 |

| 28 | - | 7 | 0.63 | 0.92 | 2.62 | 2.32 | 6.18 | |||||||||||

| 38 | - | 10 | 0.95 | 1.53 | 4.14 | 4.53 | 10.3 | |||||||||||

| 48 | 28 | 12 | 1.09 | 1.83 | 5.92 | 6.41 | 12.4 | 5 | ||||||||||

| 58 | 38 | 14 | 1.23 | 2.14 | 8.08 | 8.62 | 14.4 | |||||||||||

| 68 | 48 | 18 | 1.5 | 2.75 | 13.3 | 14 | 18.6 | |||||||||||

| 78 | 58 | 20 | 1.63 | 3.05 | 16.4 | 17.2 | 20.6 | |||||||||||

| 6.5 | 7.5 | 3.5x6x3.5 | 6 | M3 | 11 | M3 | 30 | 25 | - | 5 | 5 | 0.84 | 1.09 | 4.32 | 3.55 | 9.77 | 4 | |

| 40 | - | 7 | 1.16 | 1.63 | 7.45 | 6.59 | 14.7 | |||||||||||

| 55 | - | 9 | 1.46 | 2.17 | 11.8 | 10.6 | 19.5 | 5 | ||||||||||

| 70 | 40 | 12 | 2.01 | 3.26 | 16.9 | 18.2 | 29.3 | |||||||||||

| 85 | 55 | 14 | 2.26 | 3.8 | 23 | 24.5 | 34.2 | |||||||||||

| 100 | 70 | 17 | 2.51 | 4.34 | 37.9 | 35.7 | 39.1 | 3 | 6 | |||||||||

| 115 | 85 | 19 | 2.76 | 4.89 | 46.7 | 44.3 | 44 | |||||||||||

.png)

| Nominal model |

Main dimensions | Work surface size | ||||||||||||||

| Maximum stroke |

Width W ±0.1 |

Height M ±0.1 |

Length L |

Mass (kg) |

Workbench mounting thread hole position | Side assembly threaded hole locations | ||||||||||

| B | nxF | G | S | B1 | G1 | G2 | b1 | t1 | S1xl | T | ||||||

| VRU-3055 | 30 | 60 | 28 | 55 | 0.57 (0.3) | 25 | - | 27.5 | M4 | 39 | 15 | 5.5 | 40 | 5.5 | m3x6 | 18.5 |

| VRU-3080 | 45 | 80 | 0.8 (0.4) | 1x25 | 10.5 | |||||||||||

| VRU-3105 | 60 | 105 | 1.03 (0.6) | 2x25 | 15.5 | |||||||||||

| VRU-3130 | 75 | 130 | 1.26 (0.7) | 3x25 | 20.5 | |||||||||||

| VRU-3155 | 90 | 155 | 1.49 (0.9) | 4x25 | 25.5 | |||||||||||

| VRU-3180 | 105 | 180 | 1.72 (1) | 5x25 | 30.5 | |||||||||||

| VRU-3205 | 130 | 205 | 1.95 (1.1) | 6x25 | 30.5 | |||||||||||

| VRU-4085 | 50 | 80 | 35 | 85 | 1.5 (0.8) | 40 | - | 23 | M5 | 42.5 | 53 | 10.5 | 55 | 6.5 | 24 | |

| VRU-4125 | 75 | 125 | 2.3 (1.2) | 1x40 | 18 | |||||||||||

| VRU-4165 | 105 | 165 | 3.1 (1.5) | 2x40 | 22.5 | |||||||||||

| VRU-4205 | 135 | 205 | 3.8 (1.9) | 3x40 | 30.5 | |||||||||||

| VRU-4245 | 155 | 245 | 4.6 (2.2) | 4x40 | 38 | |||||||||||

| VRU-4285 | 185 | 285 | 5.3 (2.6) | 5x40 | 43 | |||||||||||

.png)

| Base surface dimensions Mounting hole location |

Basic load rating |

Static allowable moment |

Accuracy (μm) |

||||||||||||||||

| H | K | dxDxh | D1 | m1 | A | m2 | B2 | f1 | f2 | f3 | g | Number of rollers Z |

C KN |

CO KN |

MA N.m |

MB N.m |

MC N.m |

ΔC | ΔD |

| 9 | 10 | 4.5x7.5x5 | 7.5 | M4 | 14.5 | M4 | 40 | 35 | - | - | 10 | 6 | 2.71 | 3.67 | 12.2 | 13.9 | 51.3 | 2 | 5 |

| 60 | - | - | 10 | 4.06 | 6.11 | 33.1 | 36.2 | 85.5 | |||||||||||

| 85 | - | - | 13 | 4.68 | 7.33 | 64.6 | 59.8 | 103 | 3 | 6 | |||||||||

| 110 | - | - | 17 | 5.87 | 9.77 | 107 | 100 | 137 | |||||||||||

| 135 | - | 85 | 20 | 6.98 | 12.2 | 131 | 138 | 171 | |||||||||||

| 160 | - | 110 | 24 | 8.05 | 14.7 | 189 | 196 | 205 | 7 | ||||||||||

| 185 | 85 | 135 | 26 | 8.57 | 15.9 | 222 | 230 | 222 | |||||||||||

| 10.5 | 12.5 | 5.5x9.5x6 | 9.5 | 18.5 | 60 | 65 | - | - | 10 | 7 | 5.9 | 8.11 | 64.9 | 57.4 | 162 | 2 | 5 | ||

| 80 | - | - | 11 | 8.82 | 13.5 | 147 | 134 | 270 | 3 | 6 | |||||||||

| 120 | - | - | 14 | 11.5 | 18.9 | 200 | 214 | 378 | 7 | ||||||||||

| 160 | 80 | - | 22.5 | 18 | 14 | 24.3 | 330 | 347 | 486 | ||||||||||

| 200 | 120 | - | 22 | 16.3 | 29.7 | 492 | 513 | 594 | |||||||||||

| 240 | 160 | - | 26 | 18.6 | 35.1 | 687 | 711 | 703 | |||||||||||

.png)

| Model | Main dimensions | Work surface size | |||||||||||||

| Maximum stroke |

Width (W ±0.1) |

Height (M ±0.1) |

Length (L) |

Quality (kg) |

Workbench mounting threaded holes set |

Side assembly threaded hole locations | |||||||||

| B | nXF | G | S | b1 | b2 | t1 | t2 | S1×l | T | ||||||

| VRU-6110 | 60 | 100 | 45 | 110 | 3.2 (1.7) | 50 | - | 55 | M6 | 60 | 92 | 8 | 15 | M4 X 8 | 31 |

| VRU-6160 | 95 | 160 | 4.6 (2.5) | 1 × 50 | |||||||||||

| VRU-6210 | 130 | 210 | 6 (3.2) | 2×50 | |||||||||||

| VRU-6260 | 165 | 260 | 7.4 (4) | 3×50 | |||||||||||

| VRU-6310 | 200 | 310 | 8.7 (4.8) | 4×50 | |||||||||||

| VRU-6360 | 235 | 360 | 10.1 (5.6) | 5×50 | |||||||||||

| VRU-6410 | 265 | 410 | 11.5 (6.4) | 6×50 | |||||||||||

| VRU-9210 | 130 | 145 | 60 | 210 | 12 (7.1) | - | 105 | M8 | 90 | 135 | 11 | 20 | 43 | ||

| VRU-9310 | 180 | 310 | 17.6 (7.9) | 1 × 100 | |||||||||||

| VRU-9410 | 350 | 410 | 23.2 (-) | 2 × 100 | |||||||||||

| VRU-9510 | 450 | 510 | 28.8 (-) | 3×100 | |||||||||||

| VRU-9610 | 550 | 610 | 34.4 (-) | 854×100 | |||||||||||

| VRU-9710 | 650 | 710 | 40 (-) | 5×100 | |||||||||||

| VRU-9810 | 750 | 810 | 45.6 (-) | 6×100 | |||||||||||

| VRU-9910 | 850 | 910 | 51.2 (-) | 7×100 | |||||||||||

| VRU-91010 | 950 | 1010 | 56.8 (-) | 8 × 100 | |||||||||||

.png)

| Base surface dimensions Mounting hole location |

Basic load rating |

Static allowable moment |

Accuracy (μm) |

|||||||||||||

| H | K | dxDxh | B2 | f1 | f2 | f3 | f4 | g | Number of rollers Z |

C KN |

CO KN |

MA N.m |

MB N.m |

MC N.m |

ΔC | ΔD |

| 13 | 15 | 7×11× 7 | 60 | 90 | - | - | - | 10 | 6 | 16.4 | 22.7 | 150 | 172 | 510 | 3 | 6 |

| 140 | - | - | - | 9 | 20.5 | 30.2 | 410 | 367 | 680 | 3 | 6 | |||||

| 190 | - | 90 | - | 13 | 28.2 | 45.3 | 800 | 740 | 1020 | 3 | 7 | |||||

| 240 | - | 140 | - | 16 | 35.3 | 60.5 | 1040 | 1100 | 1360 | 3 | 7 | |||||

| 290 | - | 190 | - | 19 | 38.8 | 68 | 1630 | 1540 | 1530 | 4 | 8 | |||||

| 340 | 140 | 240 | - | 22 | 45.3 | 83.1 | 1970 | 2050 | 1870 | 4 | 8 | |||||

| 390 | 190 | 290 | - | 26 | 51.6 | 98.3 | 2750 | 2840 | 2210 | 4 | 8 | |||||

| 16 | 21 | 9×14× 9 | 90 | 100 | - | - | - | 55 | 9 | 52.3 | 75.8 | 1440 | 1290 | 2730 | 3 | 7 |

| 200 | - | - | - | 14 | 81.1 | 133 | 2810 | 2990 | 4780 | 3 | 7 | |||||

| 300 | - | 100 | - | 15 | 81.1 | 133 | 3660 | 3420 | 4780 | 4 | 8 | |||||

| 400 | - | 200 | - | 19 | 98.7 | 171 | 5710 | 5410 | 6140 | 4 | 8 | |||||

| 500 | 100 | 300 | - | 22 | 115 | 208 | 6910 | 7200 | 7500 | 4 | 9 | |||||

| 600 | 200 | 400 | - | 26 | 131 | 246 | 9640 | 9980 | 8870 | 4 | 9 | |||||

| 700 | 300 | 500 | 100 | 29 | 139 | 265 | 12800 | 12400 | 9550 | 5 | 10 | |||||

| 800 | 400 | 600 | 200 | 33 | 155 | 303 | 16500 | 15900 | 10900 | 5 | 10 | |||||

| 900 | 500 | 700 | 300 | 37 | 169 | 341 | 20500 | 20000 | 12300 | 5 | 10 | |||||

| VRU | |||

| Material | hardness | Surface treatment | |

| Mesa | 45# steel | - | blackened |

| Base | Gcr15 | HRC58~ | - |

| Track | Gcr15 | HRC58~ | - |

| Roller | Gcr15 | HRC60~ | - |

| Cage | SUS304 | - | - |

| VRUNi/Cr | |||

| Material | hardness | Surface treatment | |

| Mesa | 45# steel | - | Chemical nickel plating/low temperature black chromium plating |

| Base | Gcr15 | HRC58~ | Chemical nickel plating/low temperature black chrome plating |

| Track | Gcr15 | HRC58~ | Chemical nickel plating/low temperature black chromium plating |

| Roller | Gcr15 | HRC60~ | - |

| Cage | SUS304 | - | - |

Malaysia

Malaysia