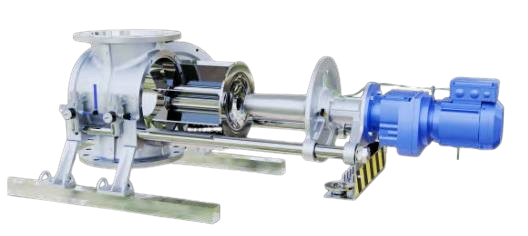

Rotary valve should be regarded as a machine, rather than a valve, to be precise.

While most valves use quarter-turn or reciprocating motion to achieve flow control, rotary valve performs the function by using an axially rotating rotor with own power. This unique feature enables the rotary valve to control the flow of powders through mechanical force. Rotary valve have solved many problems but creates many others at the same time, especially for the operations that process and food hygiene is a concern.

In order to transport the particulate materials, the rotary valve has a rotor that straddles the path where the cleaning fluid flow through during the cleaning process. It means that the rotor must be removed before a cleaning procedure, if it’s not technically possible, then the entire rotary valve must be dismantled and removed from the system before the cleaning procedure can be carried out. In the prior art, both ends of the rotor shaft are fixed by bearing seat and bearings, disassembly and assembly of the rotor is difficult that needed skillful operators and also a time consuming task. This is one of the difficulties that the powder food manufacturers are facing.

Up to date, there is no substitutes for bearings, as a matter of fact, they kept evolving better and sophisticated along with the technology. The prime task for the rotary valve manufacturers is to find new methods that can avoid the downsides of the bearing while still make the best use of them.

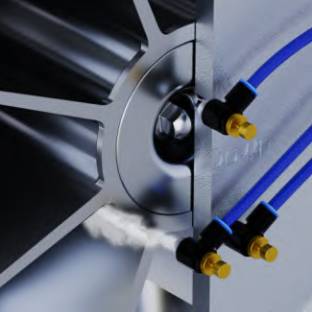

By injecting compressed air to the deep inside the rotor pockets, the shear force blow down the “sticky” materials. This method yields better results than “blow-through, ‘scraper” and caused less additional problems when dealing with the problem of material build-up

Easily removable/readily dismountable

Quickly separated from the equipment with the use of simple hand tools if necessary

[EHEDG Glossary Version 4]

As part of the requirement in food production practice, the factories undertake frequent cleaning and inspection of the equipment. It is most important to shorten the lead time of the process

Malaysia

Malaysia