Utilising Mimaki’s 6th generation LED-UV technology to cure / dry the ink instantly, combined with print speeds of up to 23m2/h, your orders can be printed and shipped the same day.

The enormous choice of print media, due to the low-heat LED-UV curing, allows you to seek new applications. Equipped with a two-layer print function using white- or clear ink and its incredible ease of use, you will not only outsmart your competitors, but exceed your customers’ expectations.

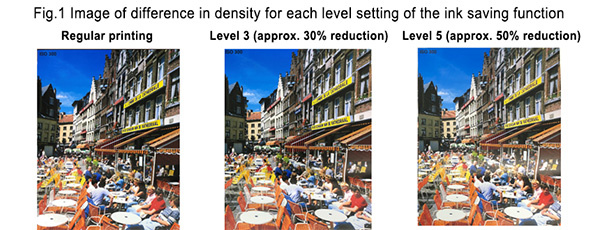

Ink saving function to reduce running costs

Reduces ink consumption by up to 50% while maintaining the color balance of the printed design. Ink reduction levels can be set with simple operations of print software “RasterLink7”, so there is no need for specialized knowledge or equipment for color adjustment.

Maximum 3-layer printing function to expand the range of applications

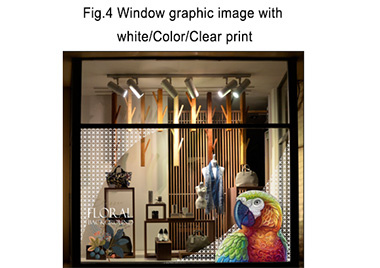

The “pull-back printing function”, which pulls back the printed substrate for follow-up printing, supports up to three-layer printing.

Conventional printers support up to two-layers printing, but it was necessary to determine whether to print white to colors or colors to white when the printer was installed.

The UJV100-160Plus has a newly added pull-back printing function that enables printing of both methods regardless of the ink color array. In addition, three-layer printing as shown ink (1) and (2) below provides printing application and added value.

(1) Colors - White - Colors: Applied to brightly colored backlit signage day and night

(2) White - Colors - Clear: Applied to window graphics with a variety of expressions

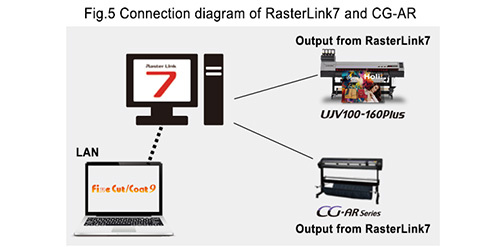

(3) Seamless linkage with Mimaki’s cutting plotter improves work efficiency

Conventional labels and stockers are produced by printing on a substrate and then using our cutting software ”Finecut9”. And output the cut data. Now, it is possible to output cut data directly from “RasterLink7” to Mimaki cutting plotter “CG-AR series”, improving the work efficiency of operators in cutting operations. This enables linking of printing and cutting even if the output PC does not have design software.

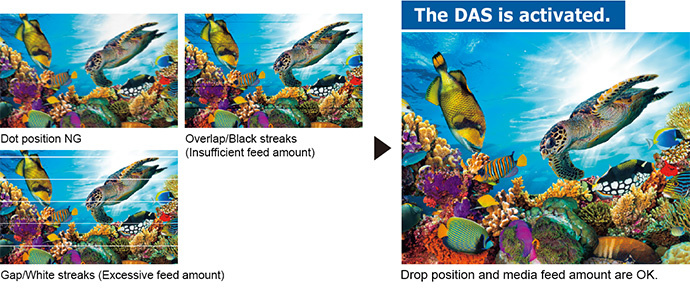

Automatic dot position and feed correction function:DAS (Dot Adjustment System)

When media or printing conditions are changed, an adjustment of ink dot position and media feed amount to suit is necessary.

As the DAS automatically performs these operations, printing can be performed without any labor or variations in adjustments by the operator.

Specification

| Items | UJV100-160Plus | ||

|---|---|---|---|

| Print Head | On-demand piezo head | ||

| Print resolution | 360dpi, 720dpi, 900dpi, 1200dpi | ||

| Ink | Type/Color | UV curable ink LUS-170 / C,M,Y,K,W,CL (Clear) UV curable ink LUS-210 / C,M,Y,K,W,CL (Clear) *1 UV curable ink LUS-190 / C,M,Y,K,W,CL (Clear) *1 |

|

| Capacity | 1L bottle | ||

| Maximum printout width | 1,610 mm (63.4 in) | ||

| Media | Maximum width | 1,620 mm (63.8 in) | |

| Thickness | 1.0mm or less | ||

| Roll weight | 45kg (99.2 lb) or less | ||

| Interface | Ethernet 1000 BASE-T, USB2.0 Hi-Speed | ||

| Power Specifications | AC100~120V/200~240V±10% 50/60Hz±1Hz | ||

| Power consumption | Max. 500W or less / Min. 4.5W or less | ||

| Safety Standard | VCCI ClassA, FCC ClassA, IEC 62368-1 ETL, CE Marking (EMC, Low voltage, Machinery directive, and RoHS), CB, REACH, Energy Star, RCM, EAC | ||

| Dimensions (W x D x H) | 2,775mm x 700mm x 1,475mm (109.3 in x 27.6 in x 58.1 in) | ||

| Unit weight | 167kg (368.2 lb) | ||