The PMT GAMMA 8-Axis is a state-of-the-art 3D laser scanning system designed to pair seamlessly with portable measuring arms. Engineered for high-accuracy measurement and rapid point cloud acquisition, the Gamma 8-Axis features an integrated rotary table that provides full 360° part access, dramatically reducing scan times while increasing coverage and detail accuracy.

Powered by cutting-edge blue laser technology, the scanner delivers superior performance across a wide range of materials—including shiny, dark, and reflective surfaces—making it ideal for use in industries such as aerospace, automotive, tool & die, energy, and general manufacturing.

Full-rotation rotary table enables efficient scanning of complex or symmetrical parts without repositioning, improving scanning speed and completeness.

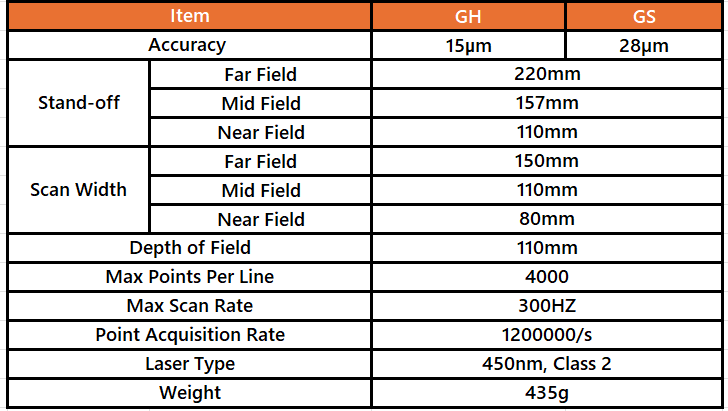

Captures up to 1.5 millions points per second with excellent resolution and reliability. Ideal for precise inspection and reverse engineering tasks.

Offers enhanced surface adaptability, allowing clean, accurate data capture from difficult surfaces such as black, glossy, or cast materials.

Automatically adjusts scanning parameters in real time to ensure consistent point quality across mixed surfaces.

Improves efficiency by covering larger areas in a single pass while maintaining high precision, even with varying surface geometries.

Compact and easy to handle, suitable for shop-floor or on-site applications.

Easily mounts on all major portable CMM arms and integrates with leading metrology software like PolyWorks, Geomagic and Verisurf.

Dimensional inspection and quality control

Reverse engineering of parts and tools

CAD comparison and product validation