SEALING AND WATERPROOFING MEMBRANE

Description

CORKJOINT® J-Seal® EX TPER Sealing and Waterproofing Membrane, made from Thermoplastic Elastomeric Rubber, is for flexible sealing and waterproofing of expansion joints subject to high movement for use in many different types of joints in concrete and over cracks, in buildings, bridges, road-works, tunnels, water works, pre-cast structures, car parks and roof slabs.

J-SEAL® EX TPER Sealing and Waterproofing Membrane is extruded from a specially compounded cross-linked TPER material that provides good resistance to UV and to certain chemicals, oils, fuels, salt and sewage water. J-Seal® EX can be fully submerged under water.

J-SEAL® EX TPER Sealing and Waterproofing Membrane provides high performance features for long-term durability and integrity of the joint, for continuous use in low and high temperatures, and has excellent UV and weather resistance.

Uses

For use in non-moving or moving joints in concrete

For use as a flexible waterproofing membrane for expansion joints subject to large movement

A joint waterproofing membrane for use in tunnels, bridges and road works

Sealing of joints in water works for water tanks, reservoirs, dams, water treatment plants, sewage

treatment plants and swimming pools, if used in-conjunction with an appropriate joint waterstop

Sealing of construction joints and expansion joints in buildings, podium decks and flat roofs

For use in wet areas where a flexible joint membrane can easily conform to joint corners in bathrooms and toilets

Trafficable joints in floor slabs if a suitable joint cover system is used as protection over the top

Sealing of joints in precast structures

Sealing of structural joints in facades

Over cracks in concrete

Advantages

Simple and fast to install. Easy to cut, weld and join

A joint waterproofing membrane and joint sealing system in one

Physically strong with high elongation capabilities

Able to accommodate movement in longitudinal, lateral and vertical directions

Ability to be installed on many different types of substrates and for use in many different type of projects

Joining of product is by heat welding providing an integrated continuous membrane

Factory made intersection pieces available for intersecting joint locations allowing for fast and easy installation

Good chemical resistance to hydrocarbons, oils, fuels and acids

Resistant to constant exposure to water

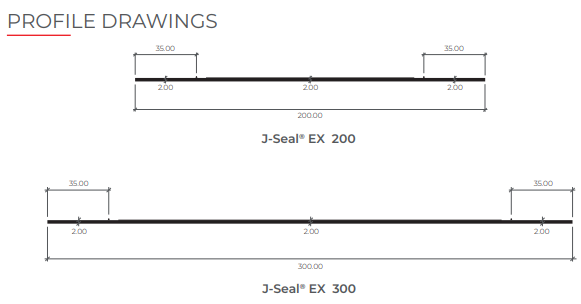

Available in widths of 200mm and 300mm for use in small or wide joints

Can be used in conjunction with other waterstop systems as added benefit/protection to the structure and to the system

Installs at a wide range of temperatures and climatic conditions with resistance to UV

Profile

Colour

Grey

Packaging

2mm (Thickness) x 200mm (Width) x 30m (Length)

2mm (Thickness) x 300mm (Width) x 20m (Length)

More detail about PINTAS TRADING SDN BHD

Malaysia

Malaysia