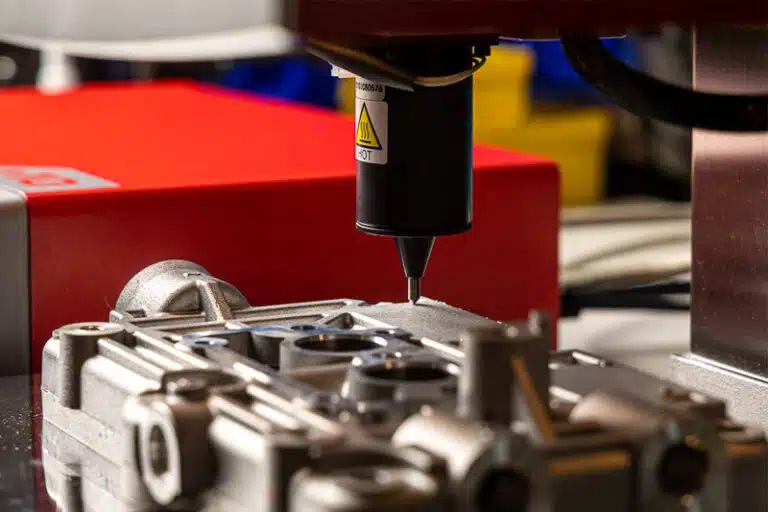

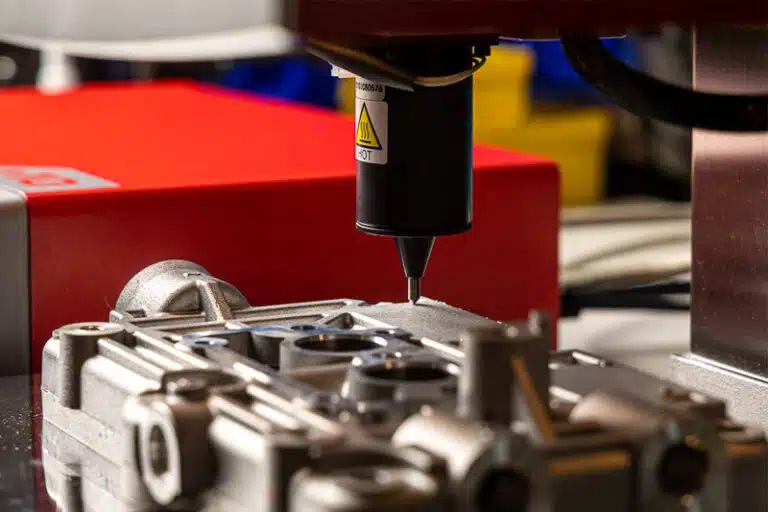

SIC Marking E10-C303 Column-Mounted Dot Peen Marking Machine

Very large marking window

Robust and reliable

Heavy use

The C303 is a

COLUMN-MOUNTED DOT PEEN MARKING MACHINE, i.e. a machine that slides on a vertical axis to adjust the position of the marking head.

It is ideal for marking small or medium sized parts, which are placed directly beneath the marking head.

It differs from other machines by its

VERY LARGE MARKING WINDOW: 300×150 mm

The C303 is a fast machine, designed for

INTENSIVE USE.

This machine is

PARTICULARLY ROBUST with a cast alloy base and a strengthened column.

It has an

INTEGRAL METER that records the piece heights, to facilitate the setting of the marking distance when parts are changed.

The

LED LIGHTING SYSTEM facilitates marking when indoor light is insufficient.

Dot peen marking technology with electromagnetic control enables parts with

various shapes and surface finishes to be marked: plane, concave, convex, circular, raw and machined surfaces.

The C303 machine can engrave alphanumeric text,

logos, or 2D Datamatrix codes.

It only needs an

electrical power supply.

The

E10 CONTROLLER that controls the C303 has a Qwerty keyboard covered by a

waterproof membrane and a

backlit colour screen that provides the user with a simple and intuitive interface.

Marking files can be uploaded/downloaded to/from the controller, to/from a PC, using a USB memory stick.

Zoom

C303 in pictures

Mechanical specifications

| Marking window |

300 x 150 mm |

| Weight |

30 kg |

| Dimensions |

385 x 350 x 704 mm |

| Stylus |

Carbide 60 mm |

Electronic specifications

| Dimensions |

322 x 380 x 112 mm |

| Weight |

5 kg |

| LCD screen |

95 x 54 mm |

| Keyboard |

Qwerty with waterproof membrane |

| Power |

300 W |

| Power supply |

Single phase, 90 to 240 V AC, 50-60Hz |

| Number of axes controlled |

2 (3rd and 4th axis on option) |

Control software

| Marking file capacity |

|

| Memory |

|

| Alphanumeric characters |

|

| Logos |

|

| Datamatrix |

|

| Fonts |

|

| Style |

|

| Rate |

|

| Font size |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

Options

PLATE BRACKET

The plate bracket is mounted on the marking station base.

It maintains a plate, maximum dimensions 145 x 105 mm, to facilitate its marking.

The benefits:

- Simple and quick cam-lock clamping

- Marking stability

- Greater freedom of action for the operator

- Fast plate marking continuity

STANDARD D AXIS FOR E10 RANGE (DIAMETER 100)

The rotary axis is heavy duty and is dedicated to the E10 range.

It can mark on the generator line of a circular piece.

A 3/4 axis board is needed for the marking controller.

There are two other large capacity rotary D axes (manual and pneumatic tightening).

The D-axis comprises:

- An 100 mm diameter mandrel with manual clamping

- An internal bit set for clamping parts on the inside: maximum clamping of the part bore 90 mm

- A bit set for clamping parts on the outside: clamping over a maximum diameter of 80 mm

- A connecting cable between the D axis and the marking controller

The benefits:

- The rotary axis allows circular parts to be marked up to a diameter of 250 mm.

- An optional soft jaw set

CONTROL PEDAL

This marking cycle start pedal relates to the E10 range only.

It is a foot-operated control.

The benefit:

It allows the marking cycle to be started with the foot

Malaysia

Malaysia