.jpg)

.jpg)

.jpg)

.jpg)

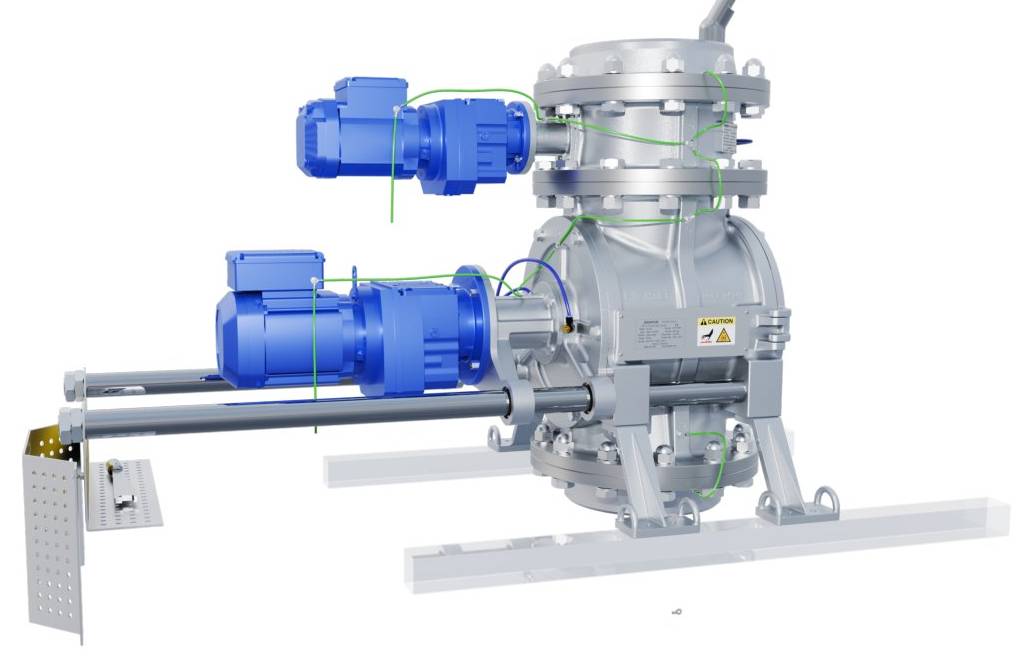

Adhesive, cohesive material stick on the surfaces wherever and whatever they pass by, the material gradually build up and then narrowing the spaces and eventually bring down the production efficiency. There is no effective solutions to prevent the build-up but only capable of controlling it down to a slower rate. Study and testing show that “Blow-Down” is an effective and better solution to deal with sticky materials. The method is about using the shear force of compressed air to blow into the deep of rotor pockets, to blow-down the materials. The rotary valve can connect to either bag/box/drum or pipeline under “Blow-Down”.

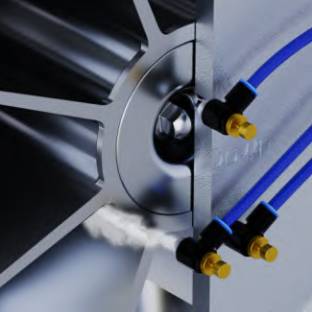

The shaft-less rotor allows the operators to use only a hand tool to assemble/disassemble the rotor with ease. The rotor is always maintaining at the axial center datum when rotating. This innovation eliminates the need of osculation detection sensors.

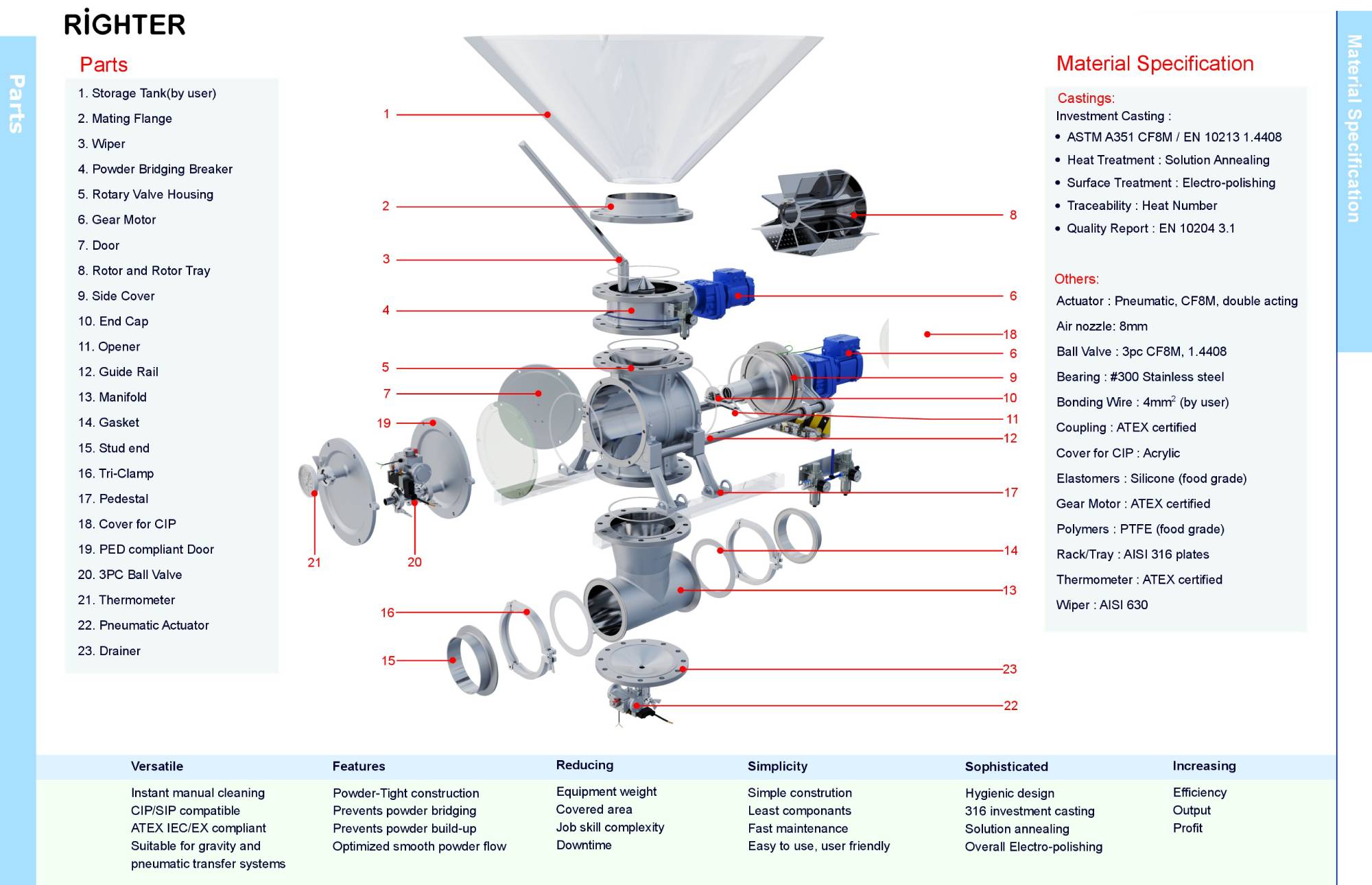

RIGHTER Powder Feeder-Discharger is an integration and collaboration of a Powder Bridging Breaker, a Rotary Valve and an Entrainment module. The unity is not only thoroughly powder tight and cleanable but also capable to do CIP/SIP integratively with the system, on top of that it’s easy to use and user friendly. Here are its outstanding features :

Note : CIP station and facilities to be provided by the user

Note : SIP station and pot water facilities to be provided by the user

.jpg)

The role of funnel is distinct from the silo in the storage tank. The function of a silo is to store and retain materials, while the funnel at the bottom, focus more on effective discharging. The cross-section area of the funnel gradually decreases in the direction of flow, forming an inverse cone. The powder flow in the funnel is restricted and becomes increasingly compact to higher density; jamming is bound to happen despite the particle's characteristics.

The cause of powder bridging is complicated. The impact severity varies due to a number of particle and environmental factors, making it difficult to choose and adopt one single measure to counteract all types of powder bridging. It is easy to tell if a silo has a powder bridging problem by looking for ‘hammer rash’ on the silo wall. If the powder is not moving freely, the operators will mostly hit the silo.

Generally, the measures to solve powder bridging are knocking, vibration, or air blowing, but the results from these methods are not entirely satisfactory, and they simultaneously cause other problems e.g. damaging the storage tank, making the powders even more compact, etc., that require additional measures.

In the case that material stops flowing, it directly affects the product quality and operation efficiency. Solving the powder bridging is the most urgent task for the factories. When all measures seem to have failed, the Powder Bridging Breaker is your righter choice.

.jpg)

The powder bridging breaker uses the power source from a gear motor to drive a wiper to rotate inside the funnel. In operation, the slow and steady motion of the wiper provides the momentum that breaks any forms of powder bridging

The Powder Bridging Breaker is made of investment casting stainless steel, it is robust and corrosion-resistant and can be applied to various types of materials.

The housing is a ring structure with a large opening to allow the powder to pass through without obstruction. A gear motor is mounted on the housing to provide the torque. The torque is transferred to the upper cap via a series of transmission mechanism, the upper cap rotates and drives the wiper to rotate in low speed.

Powder tightness is assured by effective multiple sealing measures. Cleaning is simple and easy without the need to use any tools.

Malaysia

Malaysia