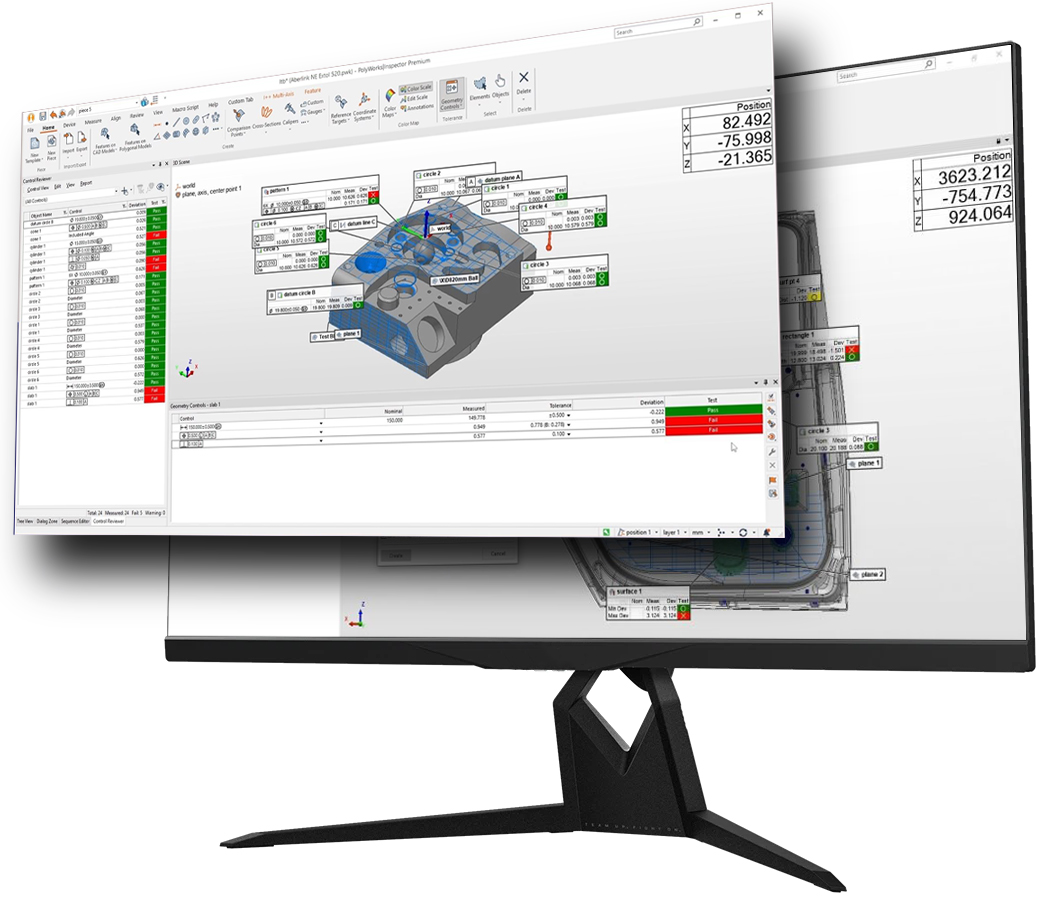

Discover The Power Of PolyWorks On Aberlink CMMs

Discover The Power Of PolyWorks On Aberlink CMMsUnleash the full potential of your Aberlink CMM with PolyWorks! Industry-leading inspection software that delivers precision, performance, and productivity without the premium price tag. From advanced GD&T tools to offline simulation and automated path planning, PolyWorks transforms your inspection process. Now with full support for Kreon Zephyr laser scanning alongside traditional touch and contact probing, it's a future-proof solution for every measurement challenge.

PolyWorks + Aberlink: Big Capability.

Small Cost.

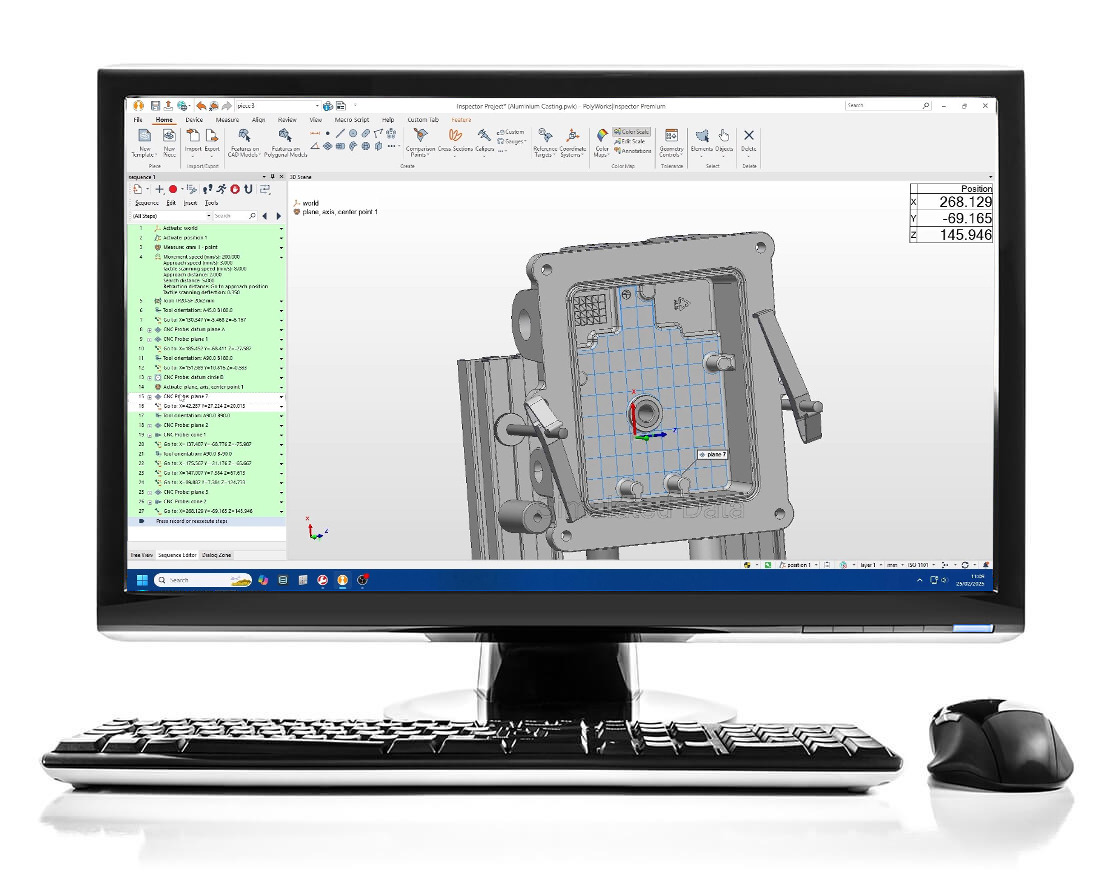

High-Productivity CNC CMM Solution

High-Productivity CNC CMM SolutionPolyWorks Inspector has reinvented the way inspection projects are set up and executed on CNC CMMs, within a flexible, user-friendly, and efficient CNC CMM operational paradigm.

Automate Quality Control Tasks

Automate Quality Control TasksMultipiece data management

Measure multiple pieces using different 3D measurement devices, and store them in a single project folder or an online data management solution using an optimal format that minimizes disk space usage.

Play Inspection Tool

Use the powerful Play Inspection and Sequence Editor tools to automate measurement workflows by ordering and triggering operations.

Macro Scripting

Add macro scripts to your measurement workflows to apply proprietary techniques, provide special feedback, or interconnect to other systems.

Measure All Required Dimensions

Measure All Required DimensionsUniversal Data Handling

Extract measured dimensions from point clouds, polygonal models, or probed points, and nominal dimensions from a CAD model or a measurement part. Seamless import of a wide range of native CAD formats. Full support for PMI (Product anufacturing Information) with autoatic feature creation.

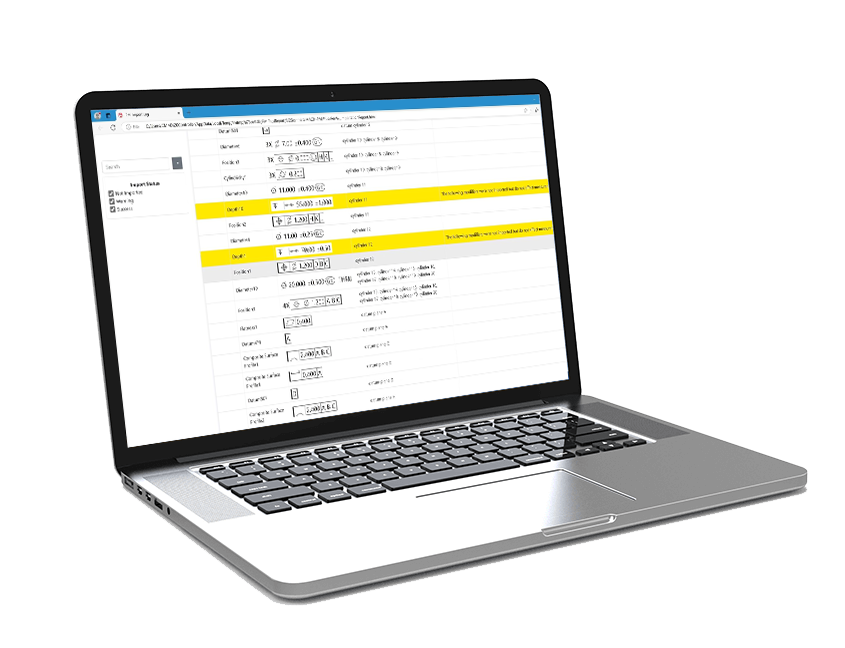

Smart GD&T

Benefit from a smart PTB-certified GD&T engine based on the latest ASME and ISO standards, with advaced DRF, material condition, datum modifier, and tolerance zone capabilities.

Deviation Analysis Using Colour Maps

Obtain surface, boundary, cross-sectional, or thickness measured-to-nominal deviations, and analyse them through a colour map display.

Profile and Flush & Gap Gauging

Evaluate advanced dimensions on fillets, design feature lines, and sheet metal part assemblies, such as radius, angle, bending, sharpness, flush, and gap.

Feature-Based Dimensioning

Measure a feature’s diameter, position, or orientation, or distances and angles between two features, in 2D or in 3D, and configure the dimensions’ display intuitively.

Airfoil Gauging

Extract advanced features on fan, compressor, and turbine blades to control and analyse dimensions, such as edge radius, thickness, length, width, angle, and area.

Malaysia

Malaysia