Panel furniture production

Cabinet and wardrobe manufacturing

Modular furniture drilling

Wood-based panel processing

.jpg)

| Six Sided Drilling Machine Configuration Table | |||||

| NO | Matter | Details | Illustrate | Remark | |

| 1 | Basic information | Basic information | Device model |

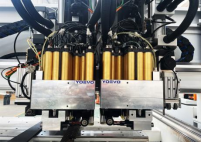

T-E12D Three Boring Head |

|

| 2 | Processing range | Processing plate size range: | Length range | 70MM-2750MM | |

| Width range | 35MM-1200MM | ||||

| Thickness range | 12-50MM | ||||

|

Processing type |

Processing hole type: see process details | Cutter | |||

| Door reaming processing method (whether independent drilling group) | Upper drilling package | Integrated in the upper drill package | |||

| Special-shaped plate (whether it can be processed) | Can be processed | ||||

| Six-sided drill gripper (fixed or not) | Smart three-level function | Exclusive patent | |||

| 3 | Device Configuration | Drill package parameters | Drill package quantity |

Upper drilling package X2 Lower drilling package X1 |

|

| Quantity of drill bits for upper left drilling package | 12 vertical drills, 6 horizontal drills, 12 auxiliary cylinders | ||||

| Quantity of drill bits for upper right drilling package | 12 vertical drills, 6 horizontal drills, 12 auxiliary cylinders | ||||

| Quantity of drill bits on the lower drilling package | 6 vertical drills, 2 auxiliary cylinders | ||||

| Auxiliary pressure plate quantity of drill package | 12 built-in drill packages are integrated as a whole | ||||

| Quantity of upper spindles | 3.5KW spindle X1 sets | ||||

| Quantity of lower spindles | 3.5KW spindle X1 sets | ||||

| Basic parameters | Program docking (file format) | MPR/XML/DXF/BAN | |||

| Usage mode (automatic connection usage) | Can be used alone or online | ||||

| Scan Mode (Scan Method) | QR code scanning | ||||

| Total equipment power | About 23KW | ||||

| Working pressure | 0.8Mpa/m2 | ||||

| Equipment net weight | About 3700KG | ||||

| Travel of each axis & maximum positioning speed & power | X axis | 130M/min/750W | |||

| Y axis | 80M/min/1.5KW | ||||

| Z axis | 50M/min/1.5KW | ||||

| U axis | 130M/min/750W | ||||

| V axis | 80M/min/750W | ||||

| W axis | 50M/min/750W | ||||

| A axis | 80M/min/750W | ||||

| Z2 axis | 50M/min/1.5KW | ||||

| Y2 axis | 80M/min/1.5KW | ||||

| Equipment size | Long | 5436MM | |||

| Width | 2880MM | ||||

| High | 2300MM | ||||

| Device name | Equipment brand | Quantity | |

| The main production equipment | High-precision automatic pentahedron gantry machining center | Imported from Taiwan AWEA | 5 |

| High Precision Vertical CNC Machining Center | CARLOS | 6 | |

| Welding Robot | JAPAN OTC | 8 | |

| Laser Fiber Metal Cutting Machine | BAI SHENG | 2 | |

| Laser Interferometer | U.K. RENISHAW | 2 | |

| Ballbar | U.K. RENISHAW | 2 | |

| Vibration Aging Meter | SHENHUA | 2 | |

| Bending machine | 4 | ||

| Sawing machines, milling machines, punching machines, etc. |

| NO | Project | Parameter Description | Remark |

| 1 | Dimensions | Length 3000mm*width 1650mm | |

| 2 | Minimum workpiece | 250*50mm Workpiece length travels along machine length | |

| 3 | largest workpiece | 2750*1200mm | |

| 4 | Workpiece thickness | 12-50mm | |

| 5 | Transfer speed | 35-80m/min | |

| 6 | Roller spacing | 110mm | |

| 7 | Input voltage | 3-380V+N | |

| 8 | Working pressure | 0.6bar | |

| 9 | Machine power | About 2.25KW | |

| 10 | Motor brand | YONGKUN | |

| 11 | Sensor brand | GERMANY SICK | |

| 12 | Pneumatic Components | AIRTAC | |

| 13 | Inverter | TAIWAN SHIHLIN | |

| 14 | Servo motor | MOSEN |

| NO | Project | Parameter Description | Remark |

| 1 | Dimensions | Length 3000mm*width 1500mm | |

| 2 | Minimum workpiece | 250*50mm Workpiece length travels along machine length | |

| 3 | largest workpiece | 2750*1200mm | |

| 4 | Workpiece thickness | 12-50mm | |

| 5 | Transfer speed | 35-80m/min | |

| 6 | Roller spacing | 110mm | |

| 7 | Input voltage | 3-380V+N | |

| 8 | Working pressure | 0.6bar | |

| 9 | Machine power | About 0.75 KW | |

| 10 | Motor brand | YONGKUN | |

| 11 | Sensor brand | GERMANY SICK | |

| 12 | Pneumatic Components | AIRTAC | |

| 13 | Inverter | TAIWAN SHIHLIN |

We supply CNC six-sided drilling machines to furniture manufacturers and woodworking factories across Malaysia and Singapore.

Local installation, commissioning, training, and technical support are available.

FAQ

Q: What is a CNC six-sided drilling machine used for?

A: It is used for high-efficiency drilling on multiple sides of panels in furniture and cabinet production.

Q: Is installation and training provided in Malaysia and Singapore?

A: Yes. Local installation, commissioning, training, and technical support are available.

Q: What types of panels can be processed?

A: It is suitable for common furniture panels. Please contact us to confirm suitability for specific materials.

Q: Do you provide after-sales service and maintenance support?

A: Yes. Local after-sales service and maintenance support are provided.

Malaysia

Malaysia