Imagine a busy, automated production line, a model of modern efficiency. Products move seamlessly from one stage to the next. Suddenly, an alarm blares and a perfectly good-looking product is rejected, diverted from the line. The cause? A signal from the conveyor metal detector. Yet, upon inspection, there is no visible metal contaminant. This scenario is a growing challenge in industries that rely on small, functional metallic components within their products, such as RFID tags.

This case study explores how a high-precision conveyor metal detector can be leveraged not just as a safety checkpoint, but as a sophisticated analytical tool to solve this exact problem. Our focus is on measuring the precise "metallic signature" of RFID tags to understand how they interact with this critical equipment.

Radio-Frequency Identification (RFID) tags are indispensable in modern logistics, offering powerful tracking and data management capabilities. However, their core component is a metallic antenna. While essential for function, this antenna can be flagged by a sensitive metal detector calibrated to find the smallest of contaminants.

The problem is complicated by a critical factor: product orientation. The way a product passes through the metal detector aperture can completely change the signal it generates. A tag lying flat might present a very different metallic profile—and thus, a different result—than the same tag oriented on its side. For manufacturers, this inconsistency can lead to frustrating false rejects, halting production and wasting valuable time.

To address this, a controlled test was designed to precisely measure the metallic footprint of several different RFID tag designs. The goal was to understand how both the tag’s design and its orientation affect its detectability.

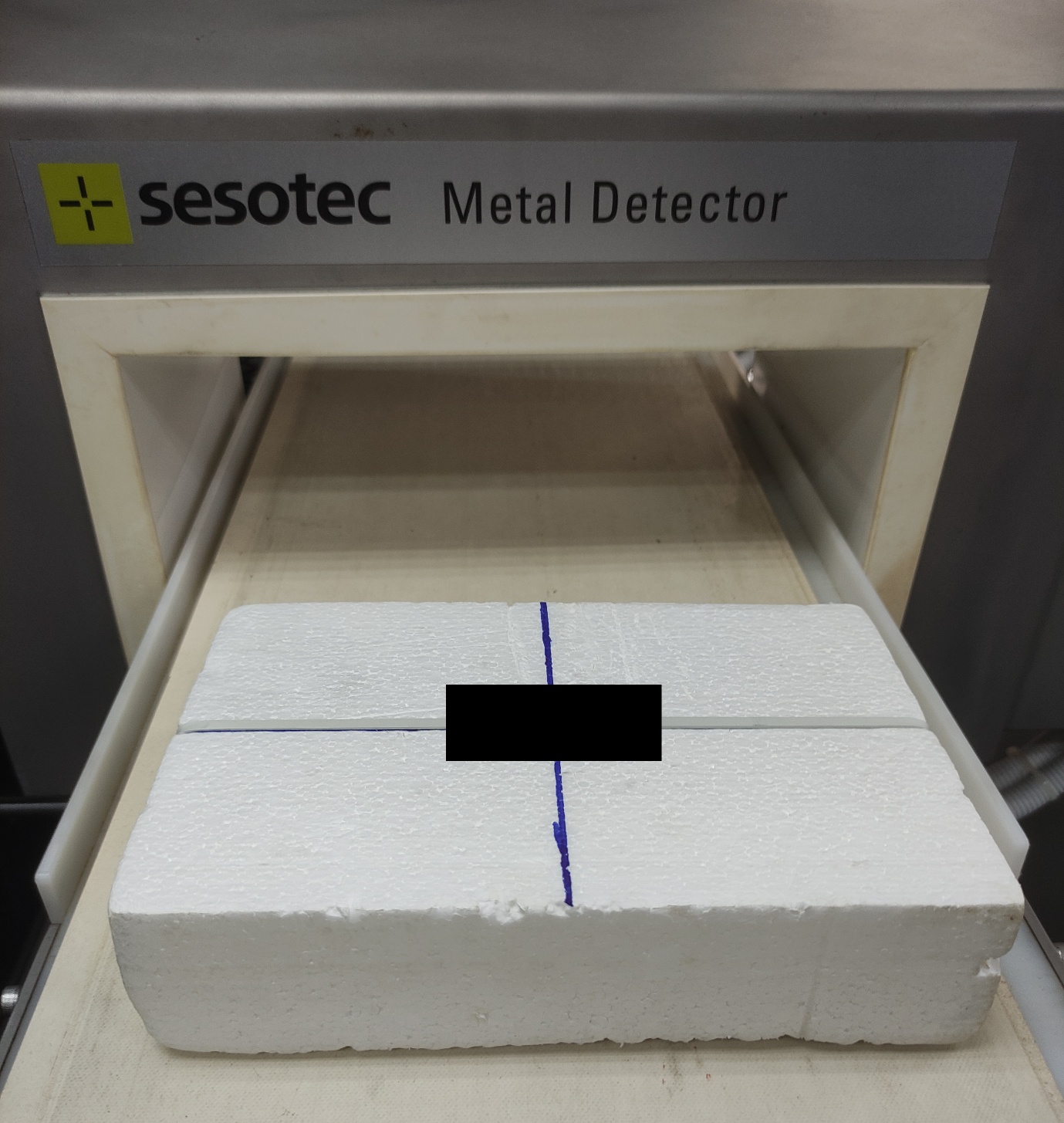

The methodology was straightforward but required high precision. Different RFID antenna designs were securely fixed in the center of a neutral block, isolating them from any other signals. This block was then passed through a high-performance conveyor metal detector. The test was repeated for each tag in two key orientations: "front-facing" (simulating a flat profile) and "back-facing" (simulating a profile on its back). This careful process allowed us to see exactly how the metal detector perceived the tags in different, realistic scenarios.

(Example of RFID Tag)

Demystifying the Results: What is "Equivalent Sphere Size?"

The results were measured in "Estimated Equivalent Sphere Size." This is not a direct measurement calculated by the equipment. Instead, it is determined through a meticulous comparative analysis.

(Example of metal test piece)

The electronic signal generated by the RFID tag inside the metal detector is carefully benchmarked against the signals from a range of standardized, certified metal test spheres. The "Estimated Equivalent Sphere Size" is the size of the official test sphere that produces the signal strength most similar to the tag being tested. This expert process translates the complex, irregular signal from the tag into a consistent and reliable benchmark that is universally understood in the industry.

Orientation is Key: For the same RFID tag, changing the orientation from front-facing to back-facing had a significant impact on its equivalent sphere size. In some cases, the reading was cut in half, making the tag far less likely to be detected.

Design Matters: Different RFID tag designs produced inherently different metallic signatures, even when their physical dimensions were similar.

This demonstrates the incredible sensitivity of a modern metal detector, which can distinguish not only between different components but also the orientation of a single component.

This knowledge is incredibly valuable. For a company developing a product that will incorporate an RFID tag, this data allows them to make informed design choices. By understanding the metallic signature of each component, they can design products and processes that avoid triggering the production line's metal detector unnecessarily.

The benefits are clear:

Reduced Downtime: Fewer false rejects mean a smoother, more continuous production flow.

Less Product Waste: Products are not needlessly discarded, saving materials and money.

Improved Efficiency: Optimizing for inspection technology boosts overall plant productivity.

Achieving this level of insight is only possible with a reliable and precise metal detector as part of the quality control toolkit.

This case study proves that a metal detector is far more than a simple safety gate. It is a high-precision diagnostic instrument that provides deep insights into your product's composition. By understanding how components like RFID tags interact with inspection systems, manufacturers can proactively solve challenges, enhance efficiency, and build more robust quality assurance processes. In the world of automated production, using an advanced metal detector for analysis is a critical step towards manufacturing excellence.

Indonesia

Indonesia